E-mail:[email protected]

Several layers of unidirectional reinforcement material (yarn, strand, roving) are stacked and oriented by means of a weft insertion system in predetermined directions that can vary widely (0° to 90°). Additional stitching yarns applied by a knitting system bind the layers together to prevent slippage. Other reinforcing materials such as chopped strand mat and tissue can be added to the multiaxial structure.

Major Applications include

The multiaxial machine is used to produce multi-layer structures for reinforcement applications. Major applications for multiaxial products include composites for the boat and shipping industries and rotor blades for power stations.

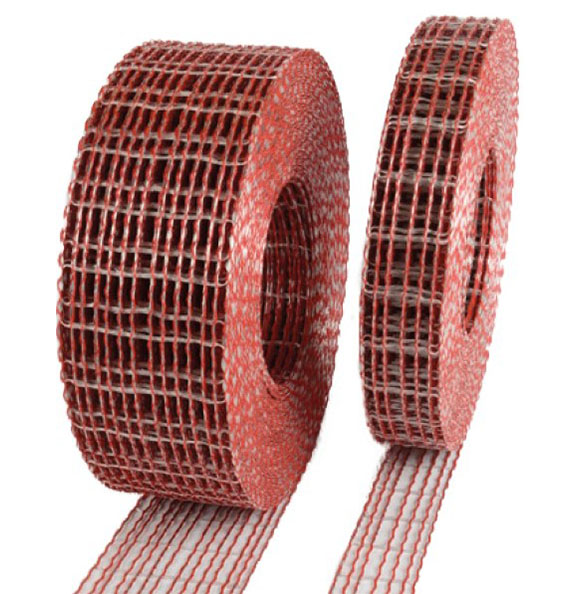

Manufacture of different types of multiaxial non-crimp fabrics composed of glass, carbon or synthetic fibers as well as hybrids of different materials,which can be used as reinforcements in road engineering ,composite materials making,etc.

Please feel free to ask anything with us. We will answer as soon as possible. Anything!

Submit Request

PDF Request

Simply fill out the form below and the catalog will be available for download!